PFAS in the production process of medication and vaccines

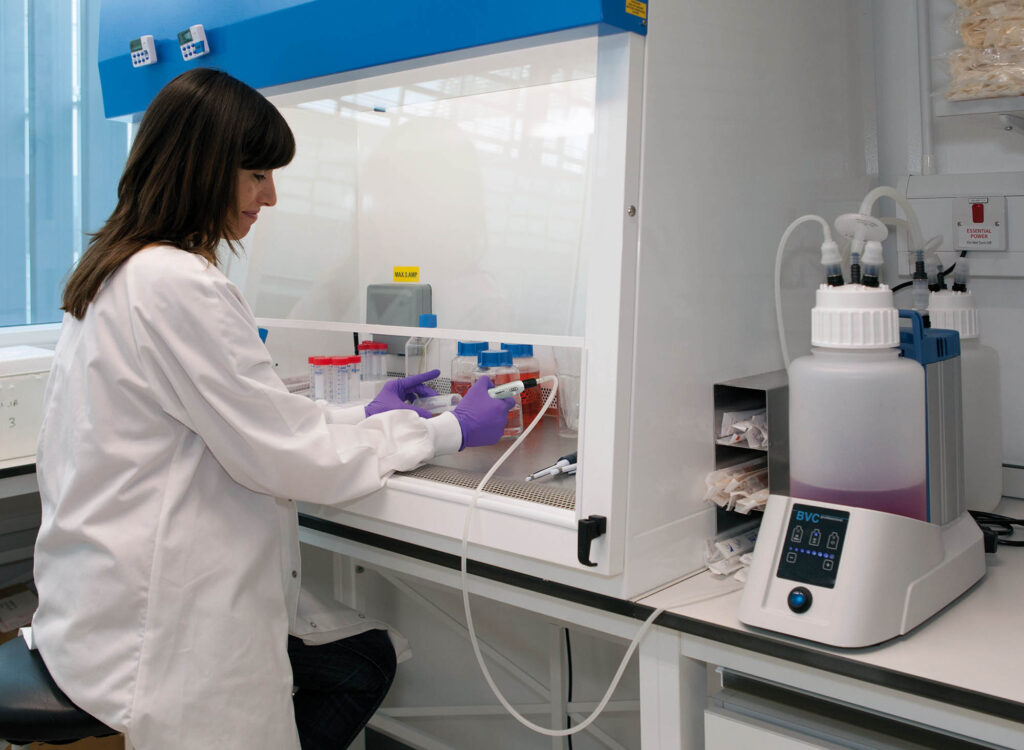

Vacuum technology, a method used to evacuate air from a closed volume, is required in all areas of science and technology, in many production processes and research. The technology is especially crucial for the development and small-scale production of vaccines and medicines in the pharmaceutical industry.

In many of these applications highly aggressive chemicals are part of the process. Thus, the vacuum pumps which are used to generate the vacuum must have a high chemical resistance in order to allow for safe and clean processes and pure products. In those chemically resistant vacuum pumps, all parts that come into contact with the chemicals are made of or covered by PFAS. These materials are inert and do not react with aggressive chemicals or the processed media. This helps to avoid contamination of the drug, which would potentially pose a health risk to the patient. The weak interaction of PFAS with other substances also contributes to better occupational safety.

The use of PFAS leads to a massive increase in the service life and total life cycle of the vacuum pumps, resulting in less waste and therefore lower environmental impact. Additionally, any chemicals used in a laboratory are disposed of according to EU standards and regulations.