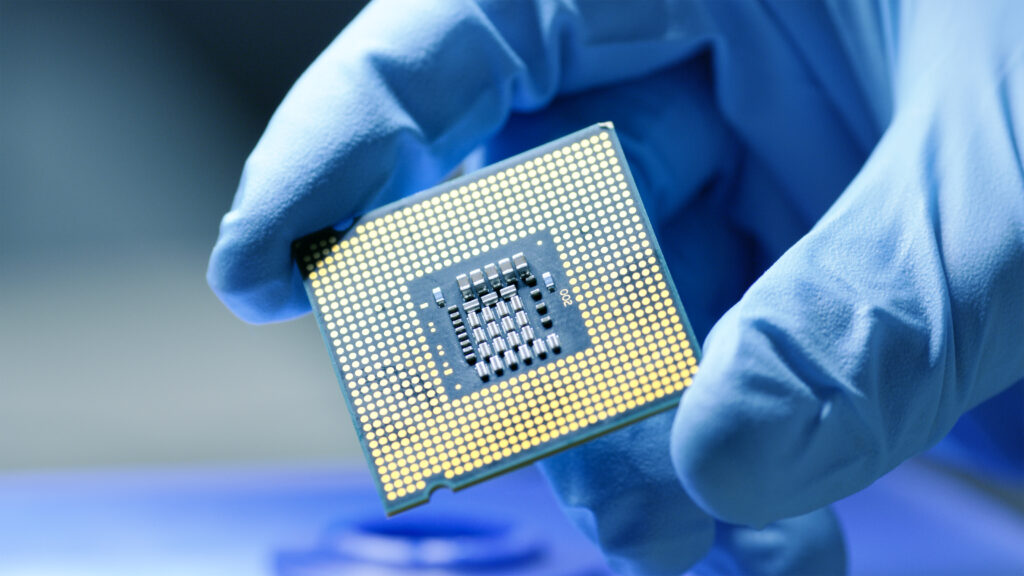

PFAS: the key ingredient in semiconductor production

Semiconductors play an essential role in today’s society, as they constitute an integral part of a wide range of everyday consumer electronics. They help to reduce society’s environmental footprint by optimising energy usage in transportation, manufacturing goods and services and thereby contributes to the achievement of the EU Green Deal objectives.

Semiconductors in transport and personal electronics

Semiconductors are not sold in stores as electrical appliances. Nonetheless, in today’s society, they are everywhere around us. For instance, semiconductors are used for various applications in modern-day cars. Apart from vehicles’ infotainment systems and air conditioning, semiconductors are essential for cars’ assistance and safety systems, such as airbags, seatbelt tensioners, ABS and stabilisation systems. Moreover, semiconductors are indispensable for the electrification of vehicles. They increase the efficiency of battery management systems in hybrid or fully electric cars, assist in recovering energy from recuperation braking systems and enable electric vehicles technologies. Another example of the widespread use of semiconductors is personal electronics, such as smartphones and laptops. The chips that operate these devices are made with semiconductors. They are responsible for the computing power, battery management, and optical sensors. A world without semiconductors is unthinkable.

PFAS as an essential process chemical

How are semiconductors produced? They undergo a complex manufacturing process consisting of more than 500 steps. One of the most crucial processes is called photolithography. A ray of photons – an intense beam of light – is used to carve miniature patterns that characterise the surface of a semiconductor. In order to avoid damaging the semiconductor by burning it with the beam of light, its surface is coated with a liquid, light-sensitive chemical which acts as a mask. The beam of light is then channelled onto the semiconductor to etch the desired pattern on its surface.

Lack of alternatives

To date, perfluorinated substances (PFAS) are the only substances that possess the properties necessary for semiconductor manufacturing. Replacing PFAS in this process would require novel chemistries to be invented, which requires extensive time and investment in research. In light of this, continued access to PFAS is a prerequisite for semiconductor manufacturing and innovation in Europe.